The storage of flammable materials in the business premises needs more than just storing them on shelves and ensuring that they are stored out of sight. These materials can be very dangerous in case of any work without any well-conceived strategy. And it is the duty of the business to provide the environment with the lowest possibility of accidental ignition. Having knowledge about the flammable nature and proper storage measures will help the companies to safeguard workers, property, and operations against avoidable damage.

Understanding Material Risks

Flammable material can be in many variations, and it can be a liquid, such as a solvent, or a solid and gaseous substance, which is used in production or maintenance. The types allow ignition points and hazards of their own. And since it is imperative that businesses recognize the particular hazard of the substances on their premises. When one knows the ease of vaporization or reaction of a material with other chemicals. One is able to find the correct storage conditions and the level of protection needed to avoid the occurrence of fire.

The behavior of these materials under various environmental conditions is also important to be taken. Temperature, humidity and air circulation are also known to affect the stability of flammables and may either reduce or increase threat. Although the containers look closed, a stuffy or hot room might cause the vapours to thicken. It also provide an environment in which a spark or friction may initiate a fire. Effective evaluation is in place to make sure that the businesses do not ignore the contribution of the environment itself to the general risk.

Organizing Storage Areas

An organized storage space is a critical aspect in reducing the risk of fire accidents through use of flammables. The commercial premises ought to ensure that sensitive areas are well separated with the normal working areas to minimize contact with a source of ignition. Storing flammable materials in areas that are not within reach of the tools. Machinery and high traffic area will greatly reduce chances of accidental contact or disruption and results in overall safety in the workplace.

Besides being separated, the storage area should also be arranged in such a way that it allows ease of movement and clear visibility. The teams should be capable of locating materials in no time without having to relocate the rest of the materials since the unnecessary handling increases the chances of spills or vapors escaping to air. Products must be categorized on compatibility but not on convenience so that substances that are incompatible with each other should not be stored next to each other. Prudent planning is a simple yet very important protection.

Using Proper Containers and Equipment

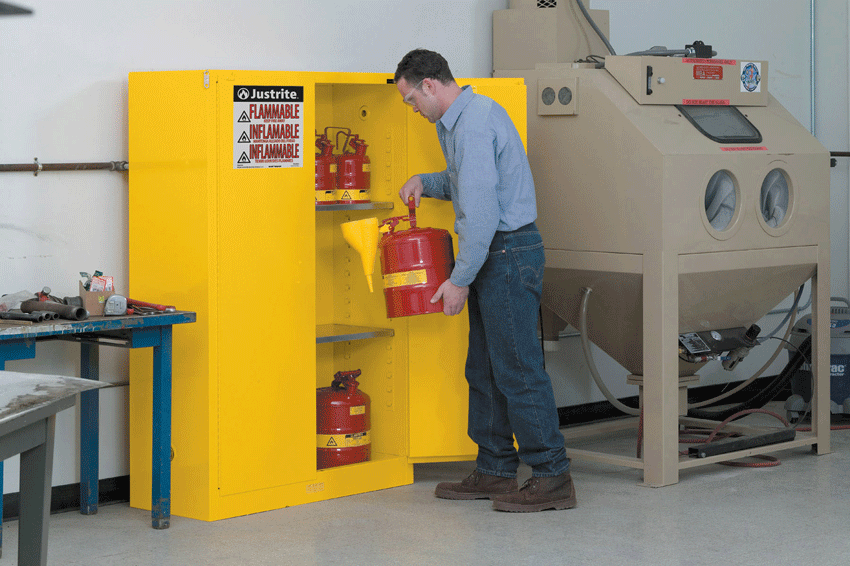

Flammables should always be kept in containers that should avoid leakages, resist change of pressure and minimize release of vapor. Safety containers used in commerce are designed in such a way that they will be intact under harsh conditions and offer a safer method of storage as compared to the improvised or repurposed containers. By choosing storage equipment for the day-to-day operations of businesses due to the durability and a chemical compatibility of the storage equipment, the possibility of accidental exposure or ignition is reduced.

Storage areas are also safe with the help of supportive equipment. A fire blanket, heat resistant tape, and proper spill control materials are some of the tools that assist the teams to put out fire emergencies swiftly and efficiently. Fire blankets can be used to extinguish smaller fires before they grow out of control and heat resistant tape can be used to provide short-term support to insulation or sealing of objects that are sensitive to heat. These are not alternative tools to elaborate safety systems, but they assist in managing the issues before they become more severe.

Maintaining Safe Conditions

After storing the flammable materials in a safe manner, the storage environment should be taken care of on a regular basis. Ventilation systems must be turned on continuously, to vent the vapors and stop the accumulation. And any trace of wear (corroded containers or decaying seals) must attract immediate remedial measures. Frequent inspections will keep storage areas clean and ensure that no debris accumulates around sensitive materials to minimize the possibility of sparks or friction.

Another aspect of maintenance is checking the safety measures and updating the employees of new practices. Workers dealing with flammables should be aware of the signs of an impending danger, position of the equipment and how to act regarding an unexpected situation. As long as these duties are seen as regular practices, instead of something one may get reminded about periodically. The safety habits may be established, and the risks of preventable incidents can be reduced dramatically.

Training Staff and Building Awareness

The training is very crucial in making sure that all people in a facility are able to know how to deal with flammable materials safely. The workers ought to be conversant with the properties of the materials around them in order to adapt their actions to fit into the environment. Also, knowledge of the risks will help the workers to perceive the storage regulations. As a safety measure instead of a convenience impediment.

There should be awareness that is beyond the initial training to continued reinforcement. Periodic meetings, exhibitions, and refresher courses aid in ensuring. That safety remains at the forefront particularly in the workplace where turnover is high or where the tasks are dynamic. A team which is properly trained stands a much better chance of becoming aware of problems in their early stages. Therefore getting minor hazards attended to in time, and continuing with the proper habits which keep commercial areas safe.

Conclusion

The storage of flammable materials in commercial areas is a continuous affair that requires knowledge, organization, appropriate equipment, and well trained personnel. Through these practices and the same standards, companies not only minimize the chances of fire. But they also establish a stable environment where employees feel secure and the operations are not affected.