Modern electronic devices are marvels of engineering, packing immense power into increasingly smaller packages. From advanced medical equipment to sophisticated aerospace systems, the internal workings of these products are incredibly intricate. At the heart of this complexity is the printed circuit board assembly (PCBA). Creating these dense and delicate boards requires more than just standard production; it demands a level of exactness that only a specialized PCBA manufacturer can provide. High-precision manufacturing is the key to turning complex electronic designs into reliable, high-performance products.

What Makes a PCBA “Complex”?

Not all circuit boards are created equal. While a simple electronic toy might have a basic, single-layered board, a high-end server or a drone’s flight controller contains a far more complex assembly. Several factors contribute to this complexity, pushing the boundaries of manufacturing.

Dense Component Layouts

Complex assemblies often feature a high density of components packed into a very small area. This is common in miniaturized devices like wearables or advanced modules. Placing hundreds or even thousands of tiny parts in close proximity without errors requires incredible precision.

Fine Pitch and BGA Components

Modern processors and integrated circuits use connections that are extremely close together. This is known as “fine pitch.” Components like Ball Grid Arrays (BGAs) have their connection points underneath the chip in a grid pattern, making them impossible to solder and inspect without specialized equipment. A single misplaced connection can render the entire board useless.

Multi-Layered Boards

To accommodate all the necessary electrical pathways in a limited space, engineers design PCBs with multiple layers. These boards can have anywhere from four to sixteen layers, or even more. Each layer contains its own set of copper traces, and they must all align perfectly to ensure the circuits connect correctly throughout the board.

The Challenges of Manufacturing Complex Assemblies

Producing complex PCBAs presents significant challenges that standard assembly lines are not equipped to handle. Errors that might be minor in a simple build can cause catastrophic failures in a high-density board.

- Soldering Defects: With components so close together, there is a high risk of solder bridges, where solder accidentally connects two points that should be separate. This creates a short circuit. On the other hand, insufficient solder can lead to a weak or non-existent connection, causing intermittent or total failure.

- Component Placement Errors: Placing a microscopic component just a fraction of a millimeter off-target can cause connection issues. High-speed automated machines are required, but they must be calibrated perfectly to achieve the necessary accuracy.

- Inspection Difficulties: Many critical solder joints, especially on BGA components, are hidden from view. It is impossible to verify their quality with the naked eye or a standard microscope. This makes quality control a major hurdle.

- Thermal Management: Densely packed components generate more heat in a concentrated area. The manufacturing process itself, particularly soldering, must be carefully controlled to avoid damaging sensitive parts with excessive heat.

How a High-Precision PCBA Manufacturer Ensures Quality

A skilled manufacturer specializing in complex assemblies uses a combination of advanced technology, rigorous processes, and deep expertise to overcome these challenges. They build quality into every step of the process.

Advanced Technology and Equipment

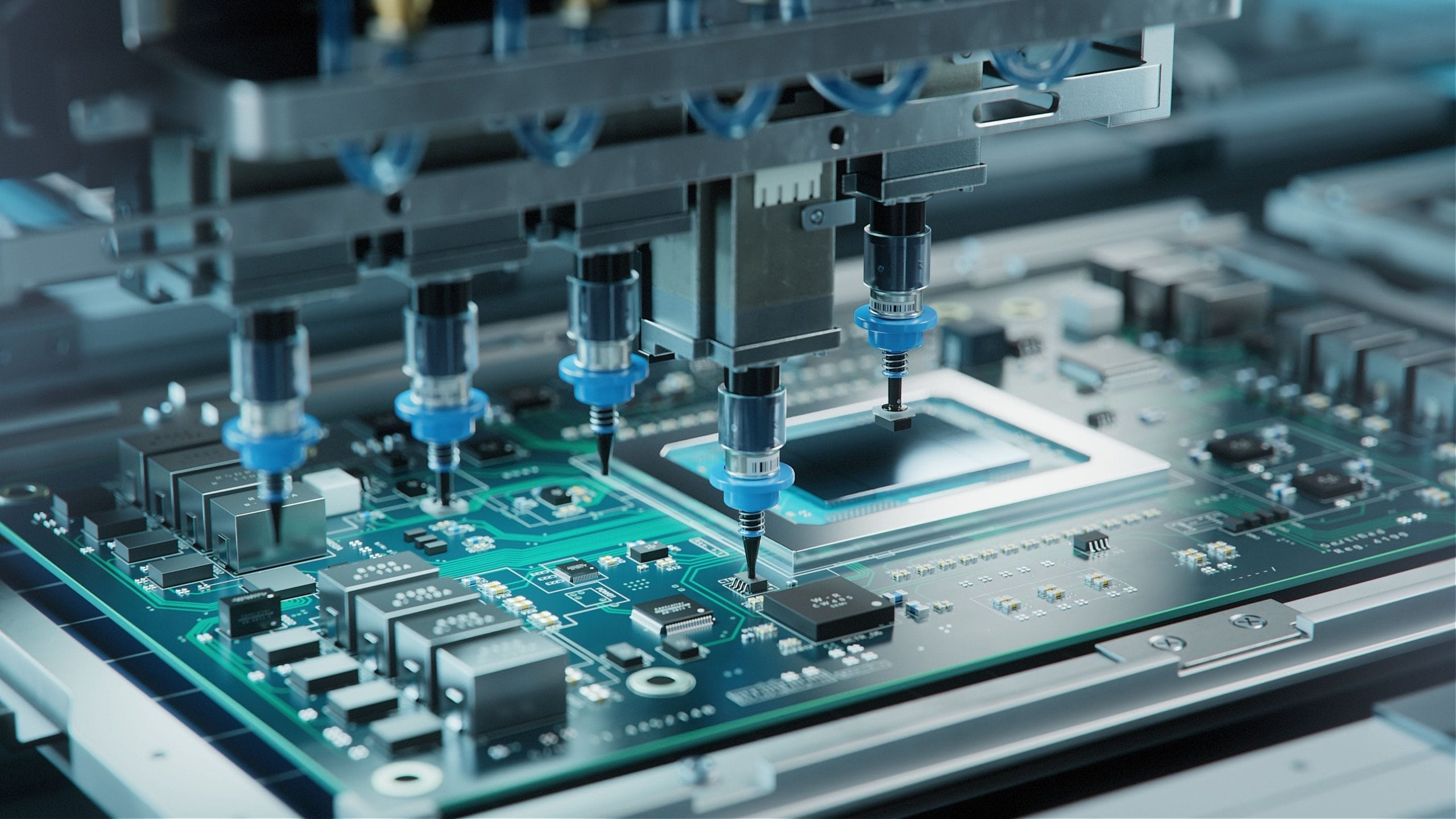

High-precision manufacturing relies on state-of-the-art equipment.

- Automated Solder Paste Inspection (SPI): Before any components are placed, an SPI machine scans the board to ensure the solder paste has been applied perfectly. This preemptively catches many potential soldering defects.

- High-Accuracy Pick-and-Place Machines: These machines are capable of placing even the smallest components with incredible speed and precision, down to the micrometer level.

- Vapor Phase and Reflow Ovens: Controlled heating is crucial. Advanced ovens ensure that the board is heated evenly and at the correct temperature profile, creating strong solder joints without overheating the components.

Rigorous Inspection and Testing Protocols

What cannot be seen must still be verified. Precision manufacturers employ sophisticated inspection methods.

- Automated Optical Inspection (AOI): After component placement, high-resolution cameras scan the board, comparing it against the design file to detect placement errors, polarity issues, and visible solder defects.

- X-ray Inspection (AXI): This is the only way to reliably inspect hidden solder joints, like those under a BGA. An X-ray machine allows technicians to “see through” the component and verify that every single ball has a solid, well-formed connection.

- In-Circuit Testing (ICT) and Functional Testing: After assembly, the board is tested electronically to confirm that all circuits function as designed. This final check ensures the PCBA performs exactly as intended.

Expertise in Design for Manufacturability (DFM)

The best manufacturers act as partners, not just suppliers. They provide Design for Manufacturability (DFM) analysis before production begins. Their experts review the design files and identify potential issues that could complicate the assembly process. This collaborative approach helps refine the design for more efficient, cost-effective, and reliable manufacturing.

Precision is the Foundation of Reliability

In fields like medical technology, automotive safety systems, and industrial automation, there is no room for error. A device failure can have serious consequences. The reliability of the final product is built upon the precision of its core components. By partnering with a PCBA manufacturer dedicated to high-precision work, companies can ensure their complex devices are not only innovative but also dependable and safe. This commitment to exactness is what transforms an intricate design into a flawless electronic reality.