In manufacturing, the drive for greater efficiency is constant. Every production manager aims to reduce cycle times, minimize waste, and enhance product quality.

While standard, off-the-shelf equipment offers a baseline for operations, true optimization often lies in solutions tailored specifically to a facility’s unique challenges and goals.

Embracing customization can unlock new levels of productivity and give businesses a significant competitive edge. This guide explores four powerful custom solutions that can help you streamline and refine your production process for maximum output and quality.

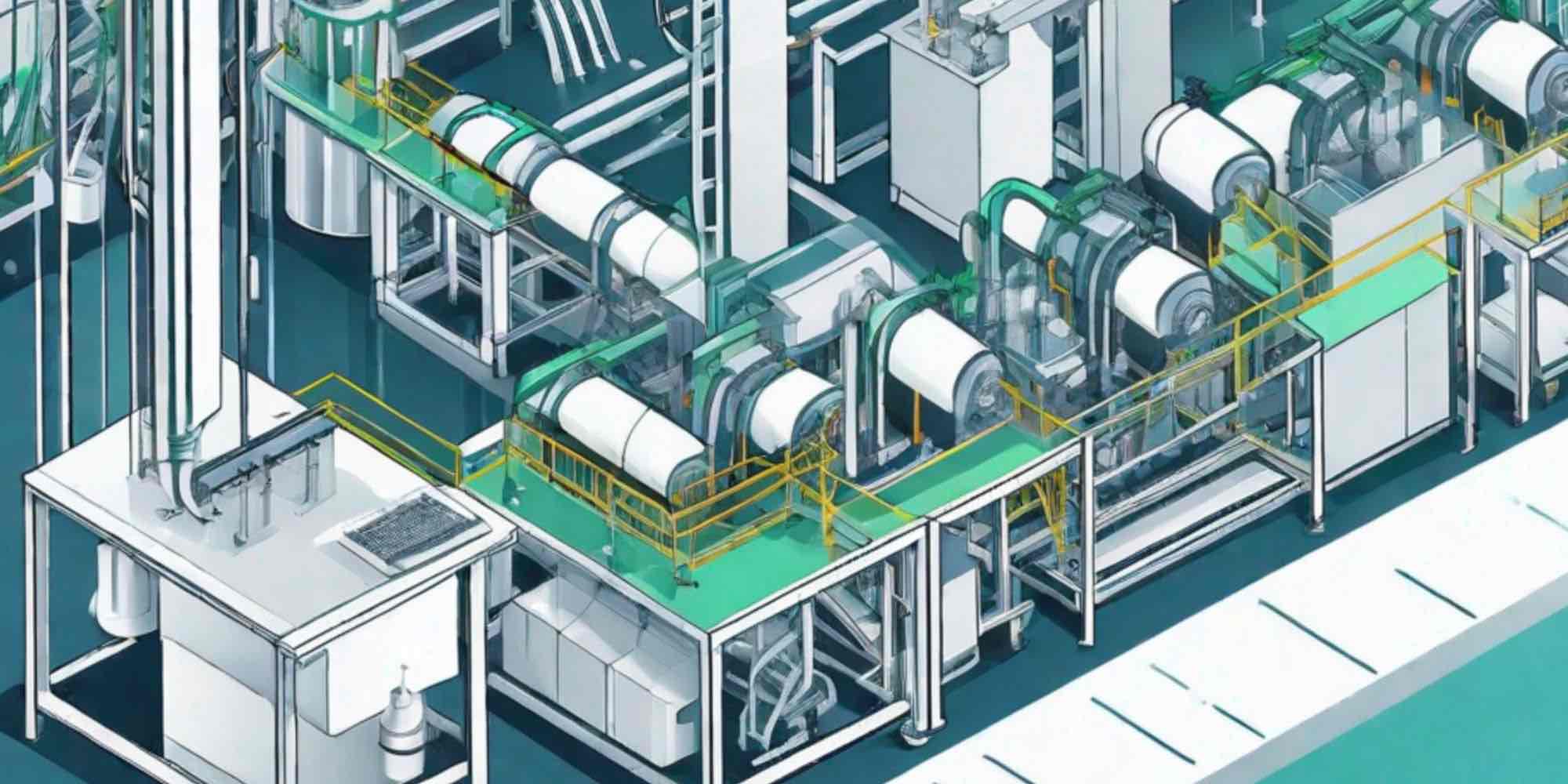

1. Tailored Machine Components and Upgrades

Standard machinery is designed to serve a broad market, which means it may not perfectly suit your specific operational needs. A common bottleneck in production lines is a single machine or component that can’t keep pace with the rest of the process. Instead of replacing an entire piece of equipment, consider targeted upgrades with custom-designed parts. For instance, a food processing plant might find that a standard conveyor belt speed is too slow for a new packaging machine, causing a backup.

A custom-built conveyor with a variable speed motor and optimized dimensions could resolve this issue, synchronizing the entire line. Similarly, upgrading a machine’s tooling to handle a new material or product shape can prevent costly downtime associated with changeovers. This approach is not only cost-effective but also allows for incremental improvements without disrupting the entire workflow. The world of custom parts manufacturing is vast, offering solutions from precision-machined gears to specially coated rollers that can drastically improve performance and durability.

2. Automated Quality Control Systems

Manual quality control is often a major source of inefficiency and human error. It can be slow, subjective, and require significant labor resources. Implementing a custom-automated quality control (AQC) system can revolutionize this part of your process. These systems use a combination of sensors, high-resolution cameras, and AI-powered software to inspect products at high speeds with incredible accuracy. For example, a pharmaceutical company could deploy a vision system that scans every pill for defects in size, color, and shape—a task that would be impossible for human inspectors to perform at the same speed.

A custom AQC system can be programmed to identify specific flaws unique to your products, flagging or rejecting non-conforming items automatically. This not only ensures consistent quality and reduces the risk of recalls but also frees up skilled employees to focus on more complex, value-added tasks. By integrating AQC directly into the production line, you can catch defects earlier, reducing waste and ensuring only perfect products reach your customers.

3. Custom-Built Jigs and Fixtures

Consistency is the bedrock of quality manufacturing. Jigs and fixtures are devices used to hold a workpiece in a specific position and guide the cutting or forming tools, ensuring every part is made to the same specifications. While standard fixtures are available, they often lack the precision needed for complex or uniquely shaped components. Investing in custom-built jigs and fixtures can provide a dramatic boost in both accuracy and speed.

For instance, an aerospace manufacturer producing intricately shaped turbine blades would benefit from a custom fixture that securely holds the blade at the precise angle required for machining. This eliminates the lengthy setup time and potential for error associated with using adjustable, all-purpose clamps. Custom fixtures are also invaluable in assembly processes, where they can hold multiple components in perfect alignment for welding or fastening. This simple solution reduces assembly time, minimizes rework, and guarantees that every finished product meets tight tolerances.

4. Integrated Production Data Dashboards

In a modern manufacturing environment, data is everything. However, collecting data from various machines and systems and then trying to piece it all together can be a monumental task. A custom-integrated data dashboard solves this problem by pulling real-time information from across your entire production floor into one centralized, easy-to-understand interface. These dashboards can be tailored to display the key performance indicators (KPIs) that matter most to your operation, such as Overall Equipment Effectiveness (OEE), cycle times, downtime reasons, and defect rates. For example, a plant manager could have a screen in their office showing the live status of every machine on the floor. If a machine stops, the dashboard can immediately display an alert with the error code, allowing maintenance to respond instantly.

By visualizing production data in real-time, you can identify trends, anticipate problems before they occur, and make faster, more informed decisions to keep your operations running smoothly. This level of insight is crucial for continuous improvement and achieving lean manufacturing goals.